MECHANICAL OVERHAUL

of AC's post-war 2 Litre SaloonCarburettors

Description

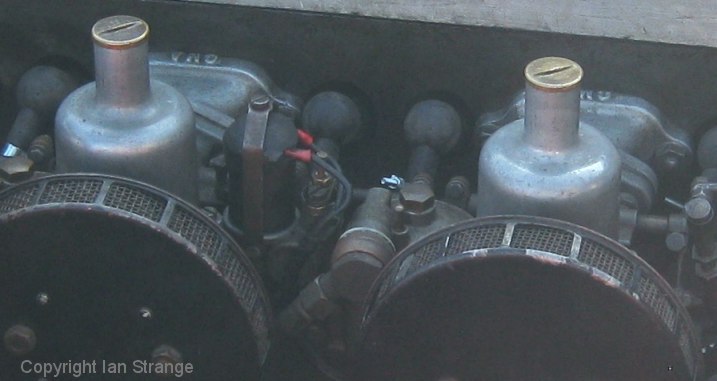

These are HV2 Thermo type carbs, 1 1/8" size. The "thermo" name refers to the automatic cold start device, which is mounted on the centre carb. The jet assembly is different from most SU carbs since there is no 'choke' mechanism. The dashpot also differs from later versions, as they have no return spring or plunger for damping. They are, however, still damped. You can demonstrate that by re-assembling the dashpot without any oil, and lifting the piston with your finger. You will feel no resistance other than its weight. If you add a few drops of oil, that will seal in the air. Try lifting the piston again, and you will feel the air being forced out through the tiny hole in the cap.

It's often mistakenly thought that the fuel quantity metered into the engine, varies simply with the lifting of the piston. In fact it's a combination of piston position, and air velocity, and this is essential for controlling the mixture under various conditions of load and RPM.

Because the AC's carbs only feed 2 cylinders each, they are less sensitive to different fuels (especially the volatility) than many other classics. As a cross-flow engine, the exhaust is on the opposite side, although the under bonnet silencers release a lot of heat. Some owners remove these and fit end-caps.

Problems and new parts

If the engine has been out of use, then problems might be due to petrol deposits that need to be cleaned out. If the carbs are worn, then most parts are still available at the time of writing (2020). The brass throttle spindles wear out, but the holes in the carb bodies seem to wear very little. The float-chamber valves wear, but the replacements I bought were partly plastic, and even more prone to jamming open if the chamber is initially empty. You can fix that dangerous issue by adding a few washers under the float, so that the valve never opens too far. Needles and jets wear out too. Check the floats for any petrol swishing around inside them due to leakage.

Ethanol in fuel means that you might want to consider replacing the cork seals with a more modern type. Interestingly, the research on seals versus fuels, shows that ethanol with little or no petrol mixed in, is less damaging to traditional seals.

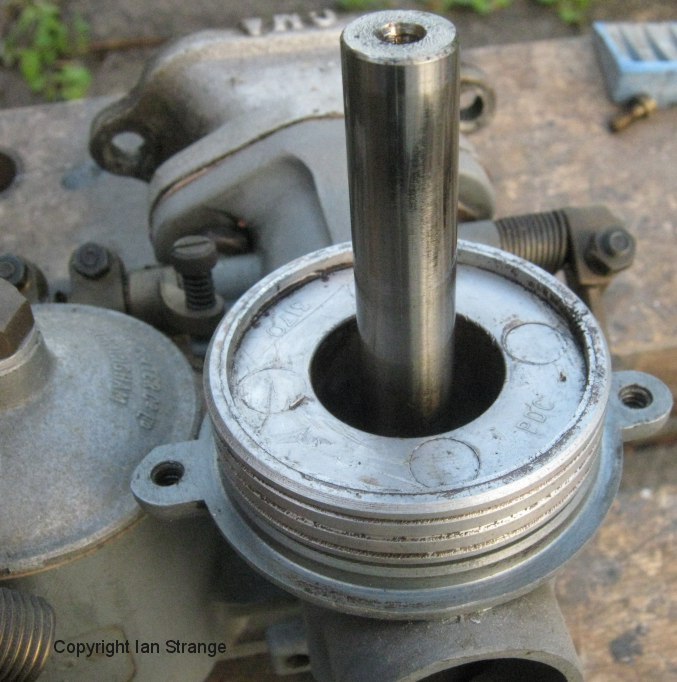

Jet assembly

The jet is held at both ends by brass bearings, with a seal (originally cork) at the top. It is spring-loaded to permit mixture adjustment with the screw underneath. The whole assembly is mounted under the carb with a hollow screw with a sealing ring. The jet needs to be centred during installation. This is done by fitting the dashpot and piston (with needle). Keep gently lifting and dropping the piston while the jet mounting is loose, and gradually tighten it up while continuing to raise and lower the piston. Carefully feel if there is any drag from the needle touching the jet. If it's still touching, slacken the carrier screw and try again. To get a sensitive feel, lift the piston with a piece of stiff wire (or something else that is light) so you can detect the slightest drag.

Above is the jet viewed after removing the dashpot and piston.

Below is the jet assembly.

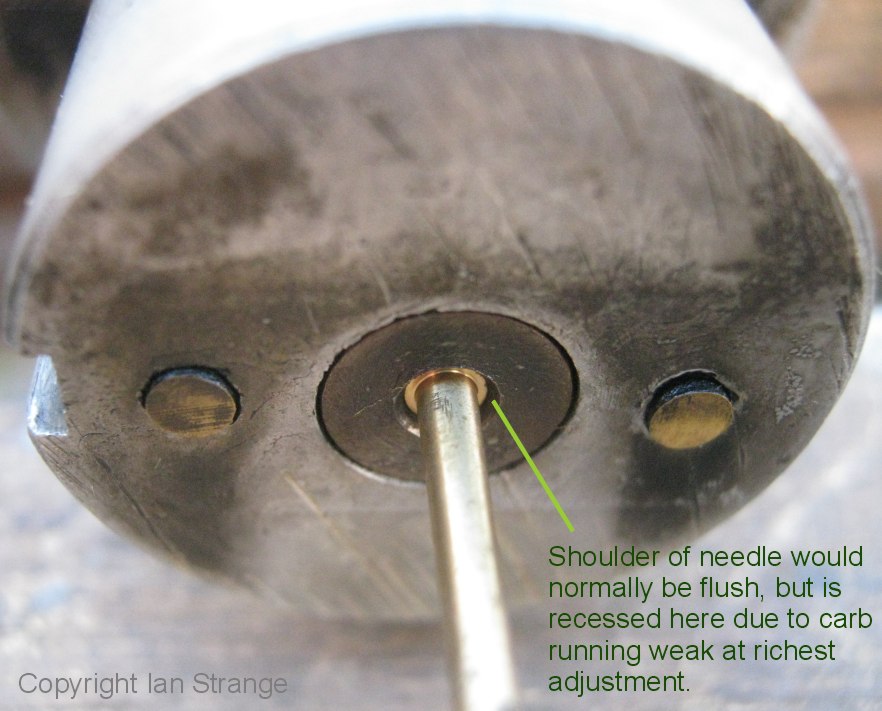

Dashpot assembly

Before removing the dashpot, mark or label it so that it can be replaced the same way round.

There are 3 versions of the metering needle: "DW" is the standard needle. "D4" is the economy (weak)version. The rich version is marked "1". The needle is fixed into the piston by a screw, and the shoulder of the needle is supposed to be flush with the bottom of the piston. However, some carbs run too weak or rich, even with mixture adjustment at its extreme. You can get around this by fitting the needle either higher or lower than that flush fitting described. Make sure that they are equal on all 3 carbs. The piston and dashpot should be clean, and the edge of the piston should not touch the dashpot as it rises and falls. The piston guide requires some SAE20 oil (bicycle oil), but only a very small quantity. Just enough to cover the rod, otherwise oil will quirt out of the vent when the piston rises. Debates over the best type of oil in dashpots, applies more to later designs with a plunger damper which uses more oil.

Float chambers

The original style all metal valves, can be machined to remove the wear ridge, or new valves obtained. Newer ones are partly of plastic and these are even more prone than the originals, to stick open if the chamber is initially empty. To solve this dangerous issue, place a few washers under the float to prevent it from dropping to the bottom. Old washers from the jet are ideal. With ethanol in fuel, keep an eye out for any leakage from the lid. One could make a viton gasket to resist modern fuel, but the thickness would have to be correct to avoid losing the float level adjstment.

Check the adjustment of the mechanism by placing a 3/8 inch rod across the underside of the lid, and the fork lever should touch the rod when in the fully closed position (the middle of the arch of the lever is the part touching the test rod). The more modern part white plastic valves, are spring loaded, so make sure you adjust to when the valve closes, without compressing the spring. If necessary, slightly bend the fork, just behind where it divides, to obtain the correct adjustment, and make sure that the 2 prongs of the fork both touch the test rod. In theory, ethanol in fuel might lower the fuel level due to the fuel being more dense - albeit by only 1% in E10 fuel. I calculated that this would lower the level by only 0.1mm (0.004 inch) which is probably within the tolerance of all the variables that affect our adjustment accuracy. That includes the thickness of the lid gasket and how tight the brass nut is.

Brass float

There is a thimble shaped filter gauze at the inlet, and so this might need cleaning (gently). And on the topic of being gentle, be very careful tightening brass nuts and screws. In fact, the thread in the base of the float chamber (with the stud) can easily strip when tigtening up. The same precaution applies when screwing in the needle valve seating into the chamber lid.

Cold start carburettor

There's not much to wear out on this device and it probably only needs new fibre sealing washers and a clean out if it's been out of use.

Finishing touches

Use some non-setting gasket sealant with new fibre washers and also on the hose screw threads. The centre carb does not have a return spring on the throttle, and it is a good safety measure to fit one.

Tuning

Adjust the mixture screws (normally covered by screw caps) to the mid-way position. Buy yourself a vacuum gauge designed for synchronising carbs. Old articles tell you to synchronise carbs by sticking a rubber tube in your ear, with the other end at the intakes, and to listen to the hissing. A vacuum gauge is far more accurate! With throttle connections slackened, and the engine running, place the vacuum gauge over each intake in turn, and adjust the throttle stops with a screwdriver until the readings are equal. Tighten the throttle linkage connections. With the engine warmed up, test the mixture adjustments. With a long-ish screwdriver, lift one of the pistons very slightly. If the engine speeds up, it is too rich. If it slows down, it's too weak. Screw in (upwards) the adjusting screw for weakening the mixture, and vice-versa. Repeat for the other two carbs. You can also try using a carbon-monoxide tester in the exhaust, which should show if the mixture is too rich. If you can see dark smoke, it's definitely too rich!

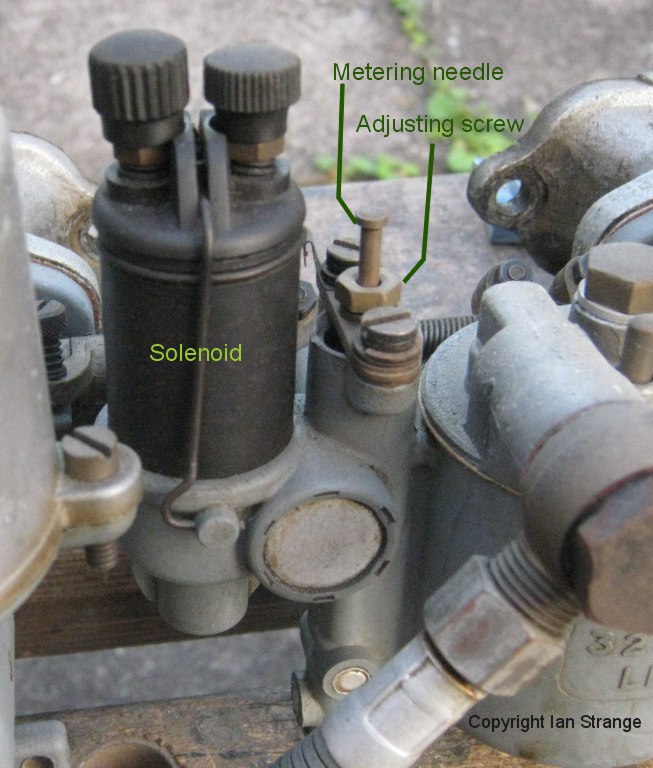

The cold start carb is also adjusted when the engine is warm. You will need to short the thermostat so that the solenoid is earthed and thus energised. Then briefly flick open the throttle to allow the thermo carb valve to open. There is a hex stop screw under the head of the metering needle. Unscrew this to enrichen until the engine is on the point of running roughly. On the next cold start up, see how it performs and enrich it a little bit more if the engine struggles to get going.

Return to the Overhaul Index